Platform is capable of surviving 120kph frontal pole test with no fire or thermal runaway, and can shorten concept to production time to 12-18 months.

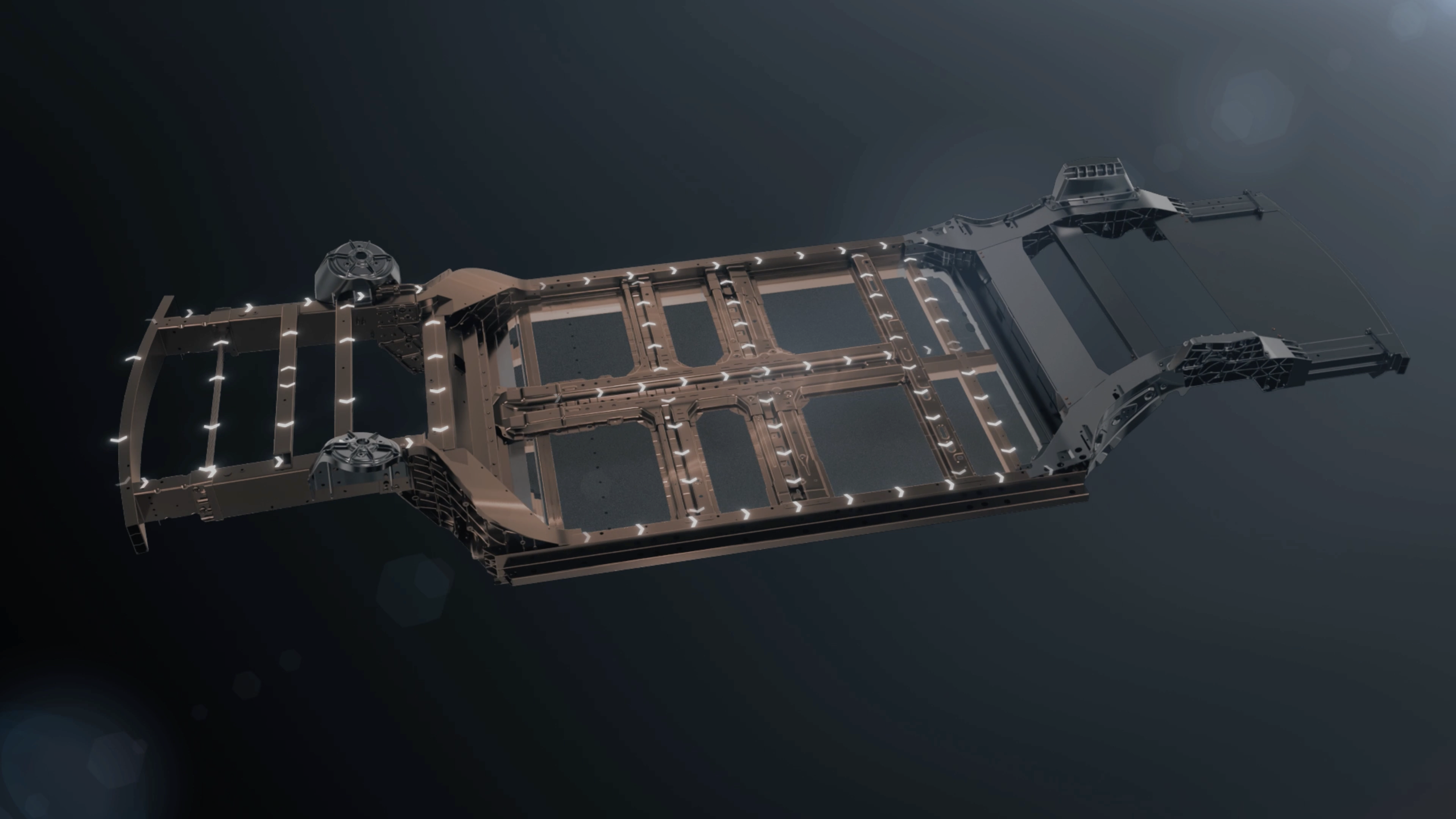

CATL, the global leader in automotive battery manufacturing, has unveiled its latest platform known as the Bedrock Chassis, a state-of-the-art skateboard chassis that claims to redefine safety standards in the automotive industry and unlock a new era of modular, personalised vehicle design.

Unveiled at an event in Shanghai as the flagship version of CATL’s CIIC (CATL Integrated Intelligent Chassis) platform, the Bedrock Chassis is the second CATL innovation reveal in just a week after the earlier announcement of their Choco-SEB swappable batteries.

Stressing the safety qualities of the Bedrock Chassis, CATL showed a prototype platform and a disguised Neta S using the Bedrock Chassis, being subjected to a frontal central pole impact test at 120kph, an impact 4.6 times higher than the standard full-width frontal crash test conducted by China’s NCAP in a more concentrated area, with no subsequent fire or thermal runaway demonstrated.

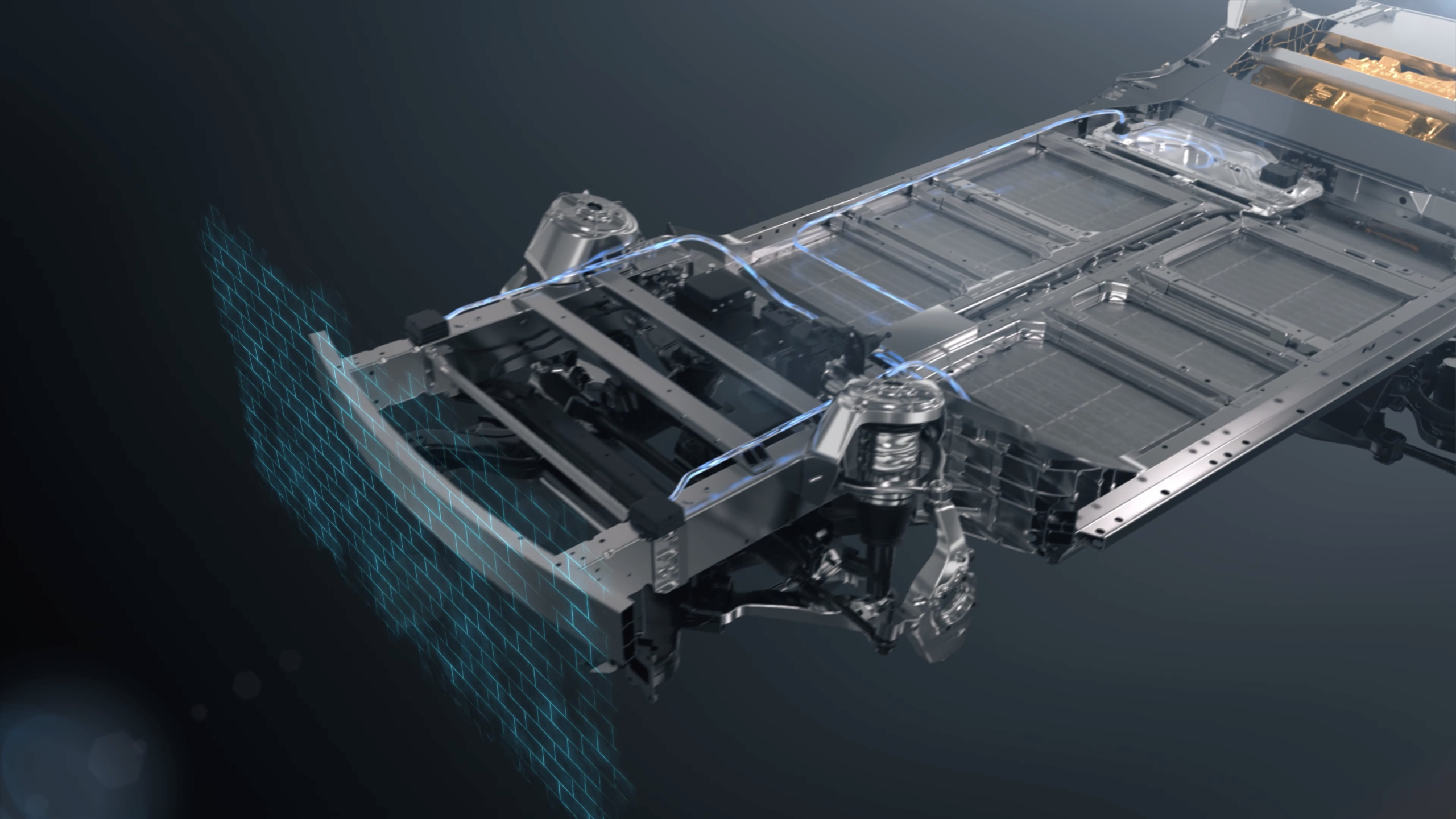

CATL claims the chassis can absorb up to 85 percent of a vehicle’s collision energy, around 25 percent more than a traditional chassis, and uses a number of innovative features to achieve this feat.

The first is to implement a three-dimensional biomimetic tortoiseshell structure, integrating both the body and energy unit framework, for what CATL calls “indestructible protection”.

This, combined with an “aircraft carrier-grade arresting structure” helps to disperse the forces of an impact across multiple pathways to decelerate the vehicle and slow or prevent intrusions into the cabin.

Like the doors on a Zeekr MIX, they use submarine-grade hot-formed steel with a strength of 2000MPA, and combine this with aerospace-grade aluminium alloy with a strength of 600MPA, to make the platform “virtually impervious”.

In addition to its structural strength, the Bedrock Chassis also showcases CATL’s latest high-voltage disconnection system, which can disconnect the high-voltage circuit within 0.01 seconds of an impact, and stop any residual high-voltage energy in 0.2 seconds.

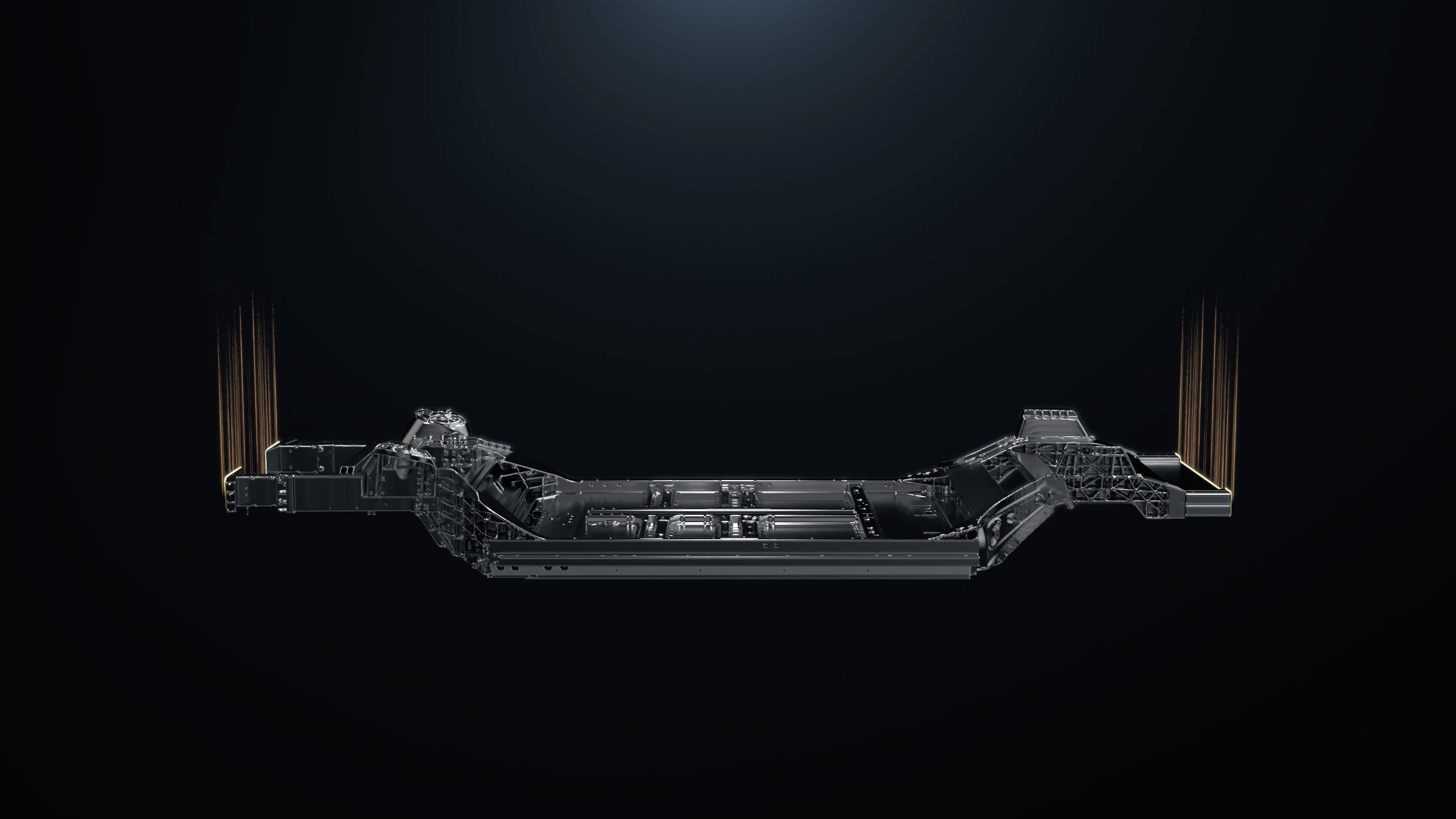

The Bedrock Chassis also aims to optimise vehicle development cycles, making it possible for manufacturers to build multiple platforms on a single architecture and go from concept to mass production in just 12-18 months, roughly halving the current cycle.

Utilising the skateboard-style platform, which separates the chassis from the upper body, should offer greater flexibility in design and the ability for niche manufacturers to tailor models to individual preferences.

With the potential to decouple the mechanical and software elements of the car, the Bedrock Chassis also makes it possible to implement both L3 and L4 intelligent driving functionalities.

AVATR will be the first brand to make use of the platform though no timeline was stated for the launch of the first models, meaning there’s no indication of which model will take the platform first.